For homeowners and businesses in New Jersey, installing an epoxy floor is an excellent way to protect and enhance your garage or basement. Below, we define common terms in the epoxy flooring industry to help you make the best choice for your space. It’s our version of Epoxy Flooring 101.

Epoxy Flooring 101: Coating Types

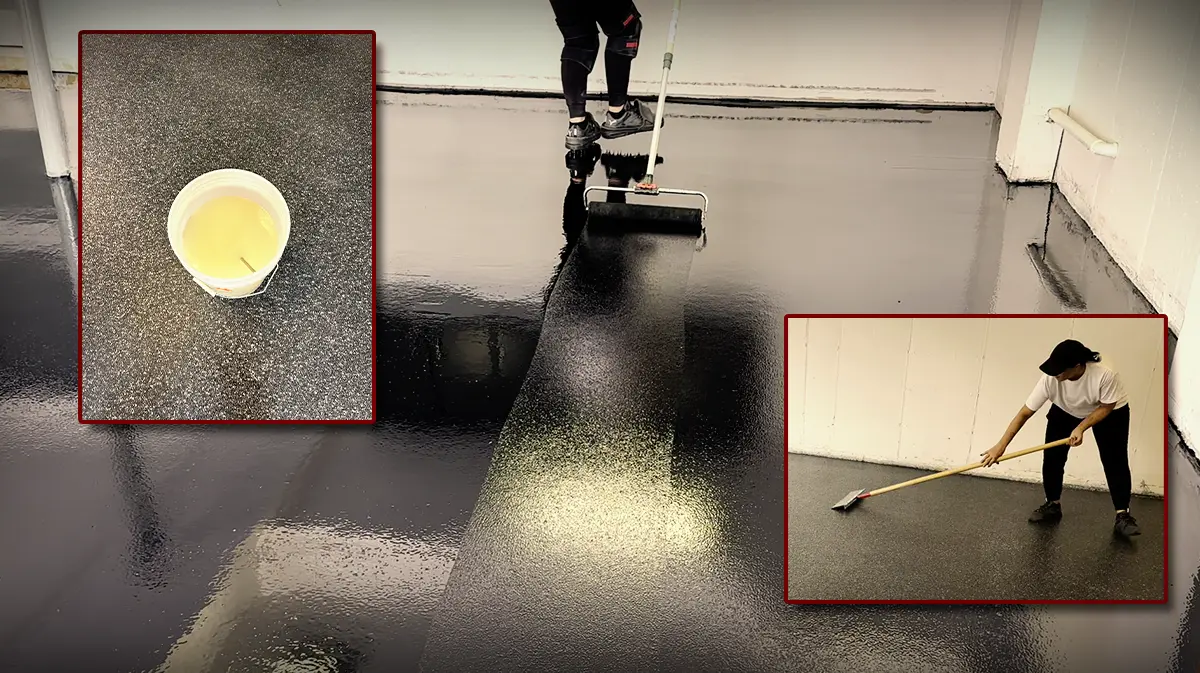

- Epoxy Coating: Epoxy are high-build, slow-cure coatings. They’re a highly durable option that resist chemical spills and abrasions. They can be used as primer coats, color coats or top coats. However, if exposed to UV light, they can amber and fade. Hence, as color or topcoats, they’re best used for interior installs. However, epoxies excel as direct-to-concrete primers (if covered by a full flake broadcast or color coat). In New Jersey, where wet weather conditions exist, epoxies provide a resilient solution for garage floors, basements, and industrial spaces.

- Polyaspartic Coating: Known for its quick curing time, polyaspartics are popular choices for outdoor applications and spaces with high UV exposure. Its resistance to yellowing and fading makes it an ideal topcoat for New Jersey garages and driveways that get plenty of sunlight. It also cures rapidly, allowing your space to be ready for use within 24 hours.

- Polyurethane: Polyurethane is typically applied over an epoxy primer as a protective top layer. Its UV resistance and flexibility ensure that it holds up well against scratches and wear, prolonging the life of your floor. However, these coatings can be odorous and aren’t resistant to hot-tire transfer. Hence, they’re more of an outdoor coating and definitely not to be used in garages.

Epoxy Flooring 101: Decorative Systems

- Mica Flakes: Mica is a natural mineral flakes that can be incorporated as part of a flake blend. Mica creates a reflective finish that adds depth and character to your floor. New Jersey homeowners and businesses often choose this system to create a high-end look in garages, showrooms or retail spaces. The shimmering effect catches the eye and enhances the overall aesthetic.

- Full Flake System: This system involves broadcasting decorative flakes called thermoplastic (or PVA) across the entire surface of the floor. It adds both durability and style, making it perfect for high-traffic areas like garages or commercial spaces. The full flake system also offers some slip resistance, which is particularly useful in wet conditions.

Epoxy Flooring 101: Protective Solutions

- Garage Floor Coating: Garage floors in New Jersey endure a lot, from road salt to vehicle traffic. Garage floor coatings, which incorporate layered epoxy and polyaspartic, offer a protective layer that’s resistant to chemicals, abrasions, and moisture. This helps to preserve the structural integrity of the concrete and enhance the garage’s appearance.

- Concrete Floor Paint: A comprehensive, layman’s term covering epoxy flooring in all its shapes and sizes. Using basic paint to coat a garage floor rarely last a year.

- Waterproofing Basement: With New Jersey’s fluctuating weather, waterproofing your basement is essential to prevent water damage and mold growth. Epoxy and polyaspartic coatings create a moisture-resistant barrier that protects the concrete from seepage, extending the lifespan of your basement floor.

- Moisture Mitigation: In a humid state like New Jersey, moisture mitigation is essential. Coatings can peel or bubble if trapped concrete moisture creates upward hydrostatic pressure. Hence, it’s crucial to address moisture levels by applying a moisture-mitigating epoxy as the direct-to-concrete primer coat. This primer acts as a moisture vapor barrier, ensuring a strong bond between the concrete and coating, even when exposed to high hydrostatic pressures.

Conclusion

New Jersey residents can greatly benefit from installing an epoxy or polyaspartic floor coating. Whether you’re seeking a durable solution for your garage, a decorative finish for your showroom, or waterproofing for your basement, understanding these key terms ensures you make the right choice. From moisture mitigation to mica flakes, these concepts will guide you in selecting the ideal coating for your needs.