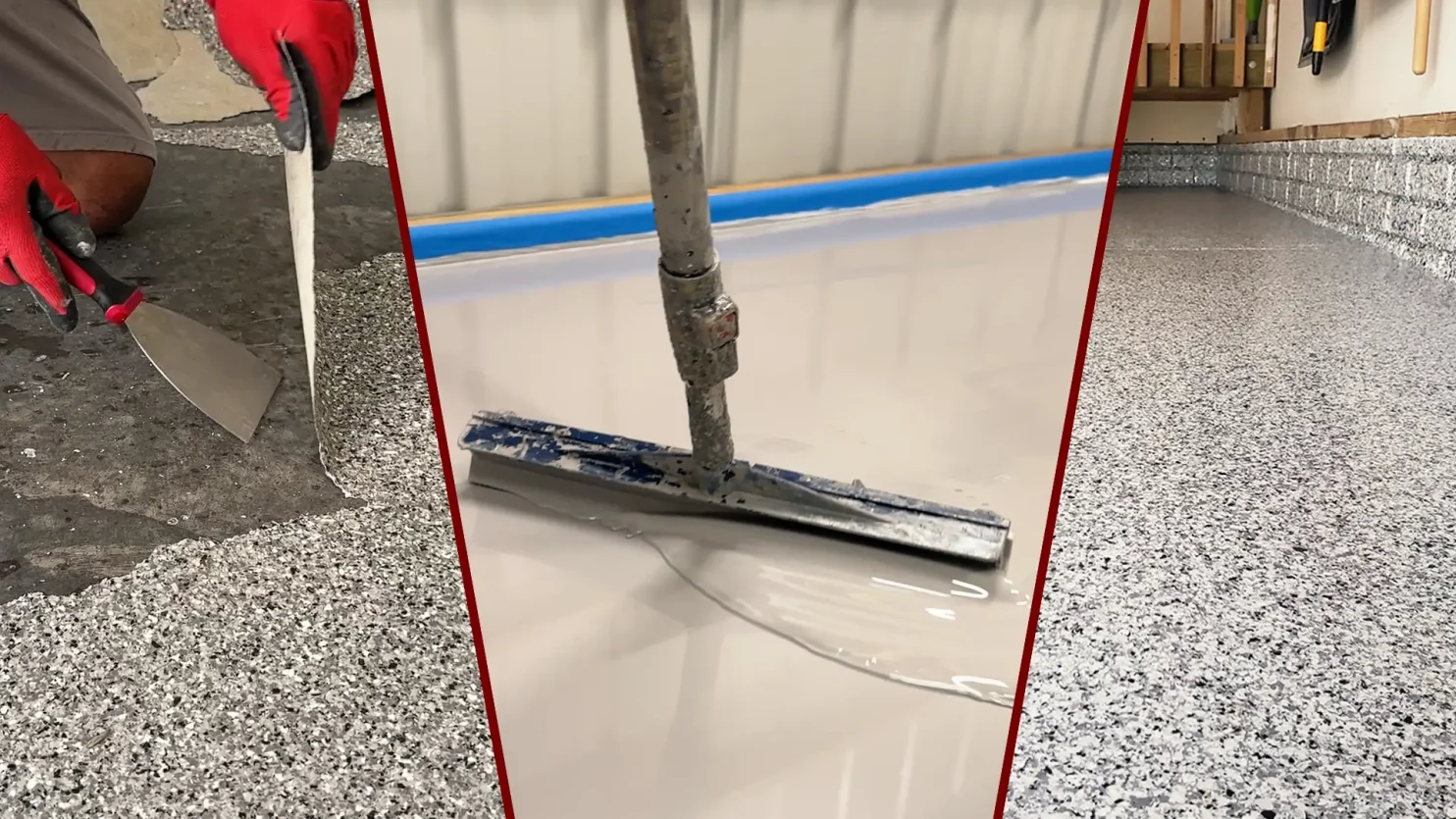

You finally decide to upgrade your garage floor—no more bare concrete, no more stains. A company offers a “1-day” coating system using polyurea or polyaspartic coatings from start to finish (base coat and top coat), promising fast results and a flawless look. But months later, the problems begin.

Chipping. Delamination. Moisture bubbles.

What went wrong? At Garage Floor Coating of New Jersey, we’ve seen these scenarios far too often. And the issue almost always starts at the bottom—with the base coat. That’s why we rely on garage floor epoxy to build every floor the right way.

Fast Doesn’t Mean Strong

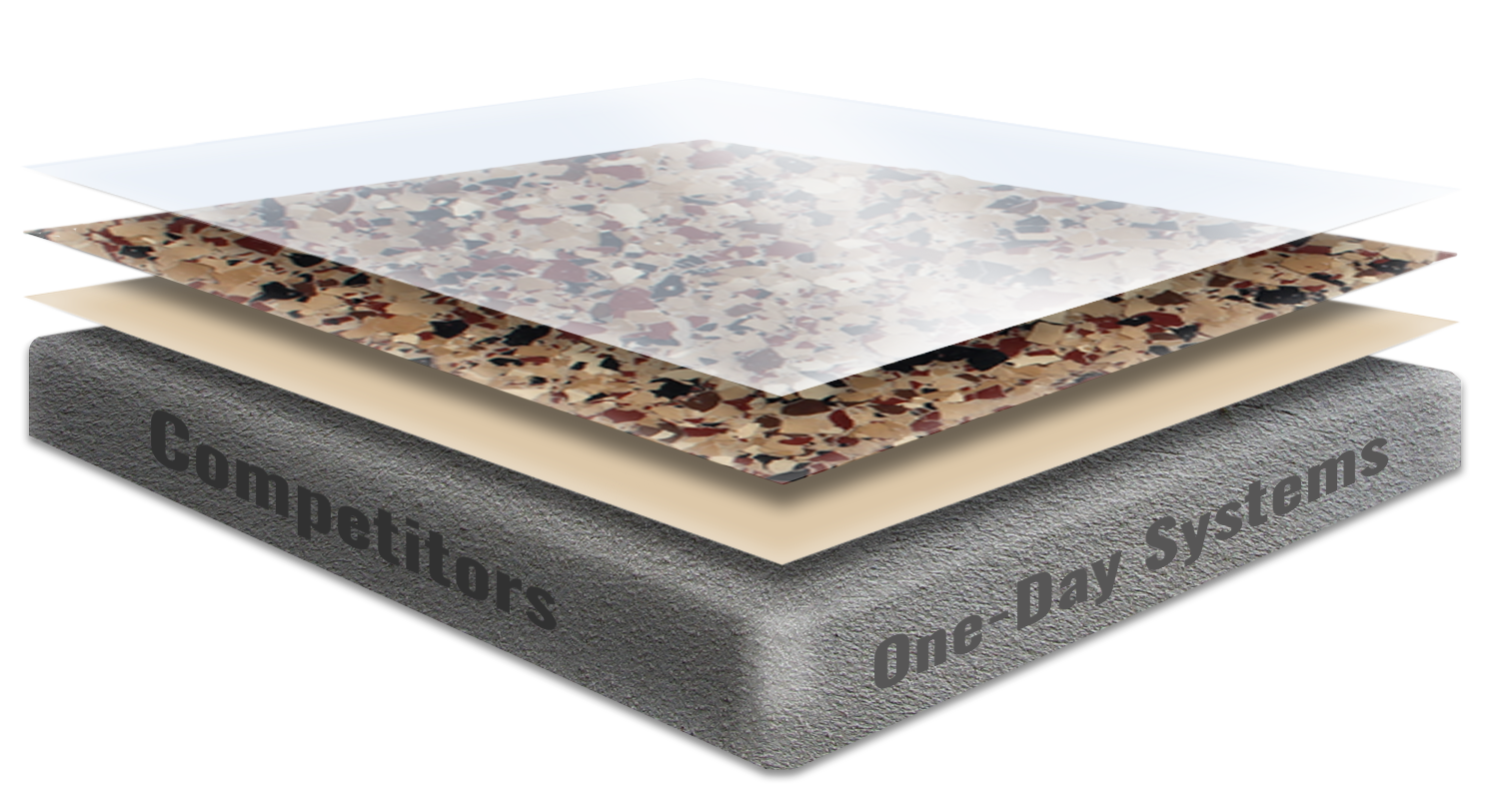

Polyureas and polyaspartics are quick-curing coatings. They cure in under an hour and even faster in the presence of medium to high moisture conditions. That might sound like a perk, but when used as direct-to-concrete base coats, it doesn’t give the material sufficient time to deeply penetrate the concrete.

- What can go wrong?

If the coating does not deeply penetrate the concrete, it hasn’t strongly bonded. With vapor pressures from below, the coating lifts or peels…not uncommon in New Jersey’s seasonal climate.

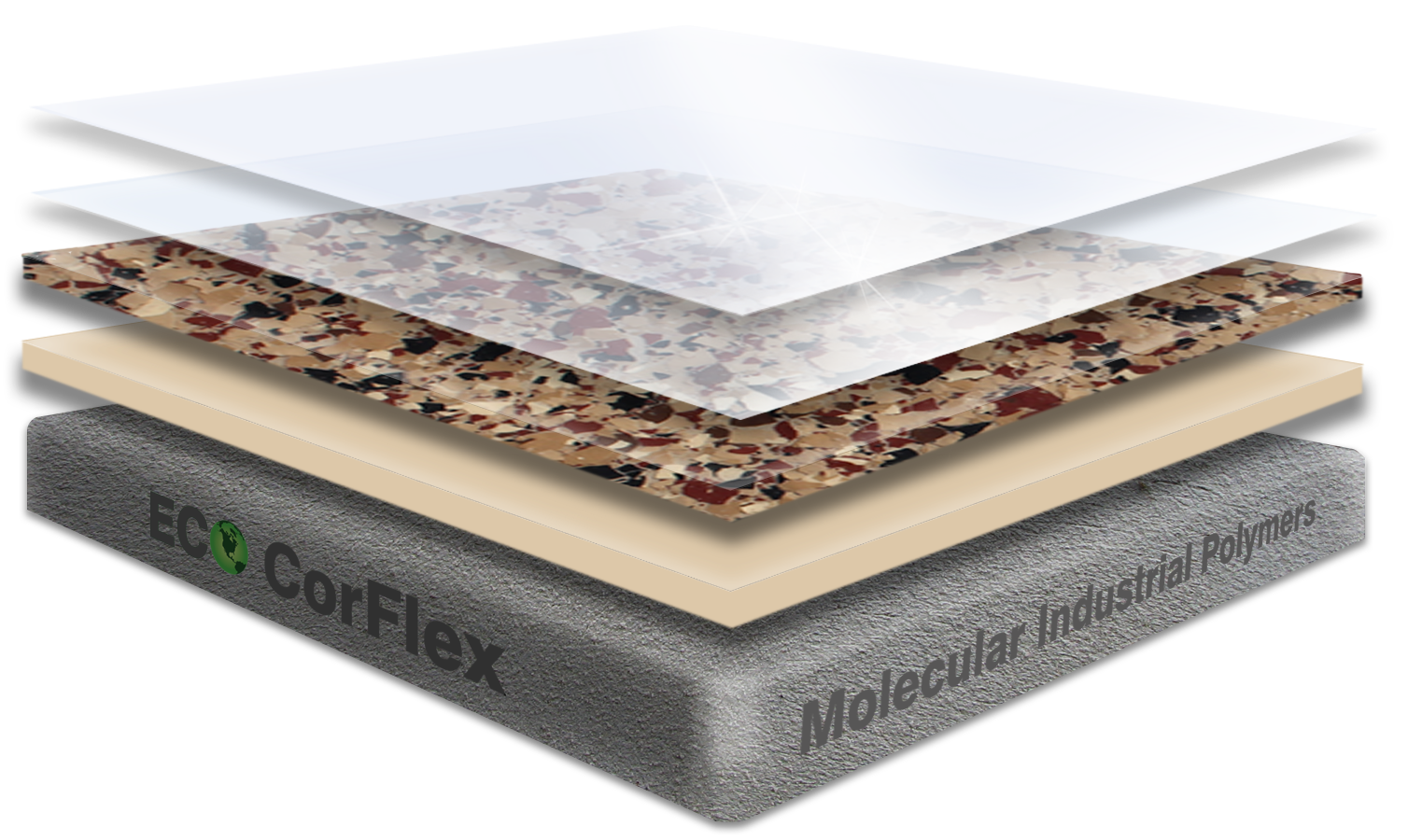

Conversely, epoxies are slow cure coatings. When used as base coats and allowed to cure overnight, they deeply penetrate and bond with the concrete substrate, creating a solid anchor and moisture vapor barrier.

Moisture Pressure? It Happens Here, Too

New Jersey’s humid summers, rainy springs, and coastal influence mean your garage slab isn’t immune to moisture issues. Concrete is porous and moisture wicks its way upwards from below. Over time, it creates a hydrostatic pressure that pushes up on the applied coating. If your base coat is thin and poorly penetrates the concrete, expect bubbling, blistering, and early failure.

A garage floor epoxy creates a reliable moisture barrier. Polyurea-polyaspartic base coats just can’t offer the same level of defense.

Thinner Base = Weaker Floor

In addition, polyurea-polyaspartic coatings, due to their inherent chemical nature, can’t be applied thickly (they just won’t cure). So, they must be applied thinly. The thin, poor-penetrating base coat can’t handle high hydrostatic pressures (precisely why these installers won’t warrant “moisture-related issues”). Conversely, epoxy is a “high-build” coating allowing for thick application. It gives your garage floor a durable foundation that lasts longer and resists moisture and wear far better.

GFC of New Jersey: Doing It Right from the Ground Up

We never use polyurea or polyaspartic coatings as direct-to-concrete base coats (we reserve them as clear top coats only). Our 2-day system includes:

- A slow-curing, moisture-mitigating, 100%-solids garage floor epoxy base coat

- Two 100%-solids polyaspartic topcoats for UV, impact, stain and chemical resistance

Don’t gamble with a shortcut. Choose Garage Floor Coating of New Jersey and get the garage floor that’s built to handle life in the Garden State.