Exposing the Truth Behind “One-Day” Concrete Coatings

In a GarageFloorCoating.com article circulated in August 2020 (“Polyurea-Polyaspartic One-Day Systems: Do They Work“), the issues relating to “one-day” coating systems were examined. These garage floor coatings have surged in popularity due to their quick and convenient application and product/labor “efficiencies” for contractors. Similarly, customers value them because they can be installed quickly – within a single day. However, it’s crucial not to forget the age-old advice of caveat emptor (“Let the buyer beware”).

In this article, we’ll expose the truth behind “one-day polyurea” and “one-day polyaspartic” concrete coatings, showing that speed and quality simply don’t equate.

Understanding the Difference Between a Polyurea and a Polyaspartic

Polyureas and polyaspartics are two-component liquid coatings, well-regarded in the concrete coatings industry. The terms “polyurea” and “polyaspartic” are often used interchangeably given that a polyaspartic is in fact an “aliphatic polyurea”. These two coating products have similar chemistry, with one critical difference. Polyaspartics (aliphatic polyureas) are chemically-modified versions of polyureas, altered to slow down their cure rate. Why is this important? Because “pure” polyureas cure so quickly (in seconds; they’re often used to coat truck beds) that they require specialized equipment, like portable reactors, to apply them! This is not ideal when using polyureas as concrete coatings; applicators need a slowed-down version, like the polyaspartic, so they can coat concrete using simple rollers and squeegees…negating the need for specialized equipment.

Polyaspartics (or aliphatic polyureas) are excellent liquid coatings. They possess a rapid curing capability and extreme UV, chemical and impact resistance. They can also prevent hot-tire transfer (“plasticizer migration”)…staining that’s caused by high-end car tires.

The Limitations of Polyurea-Polyspartics

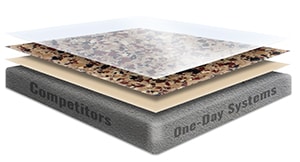

However, even high-quality polyurea-polyaspartics possess one significant flaw – they’re simply unsuited for use as direct-to-concrete primer coats, especially concrete exposed to medium to high moisture conditions. Polyurea-polyaspartics don’t penetrate into concrete well, and due to the way in which polyurea-polyaspartics cure, they can’t be applied thickly. They’re only designed for thin-to-moderate film builds. And these limitations create a problem. Porous concrete, exposed to moderate to high moisture conditions, builds hydrostatic pressures that can push up on an applied coating. A wafer-thin layer of polyurea-polyaspartic applied as a primer coat (as it is in “one-day” systems) can result in peeling over time. “One-day” contractors know this, so they alter their warranties to include warranty exclusions to “moisture-related issues” and/or “high hydrostatic pressure”. Some contracts won’t even warrant staining due to hot-tire transfer.

So why would any contractor take this chance? Because “one-day” systems require less coatings and less labor. So the profit margins are great…for the contractor!

Correct Application Using an Epoxy Primer

Expert (honest) contractors overcome this issue by applying a moisture-mitigating epoxy as the base coat…only using polyaspartics as clear topcoats. Why? Because epoxies penetrate concrete very well and cure differently. The thicker the epoxy mass (the thicker the coat), the faster an epoxy cures. (Epoxies are called “high-build” coatings). Due to these properties, epoxies make for great primer coats! Albeit, they possess their own limitations! They “amber” or “chalk” when exposed to sunlight and don’t possess the same extreme chemical protection that polyurea-polyaspartics do. In addition, epoxies require a longer cure time, so installations typically take longer than one day to install.

So each coating type possesses unique strengths and weaknesses. Epoxies are excellent primers, but are unsuitable as topcoats if exposed to UV light. Conversely, polyurea-polyaspartics make fantastic clear topcoats, but fail as effective primer coats due to their poor performance when subjected to high hydrostatic pressures (resulting in delamination). So the best concrete coatings employ the benefits of both coating types!

Us VS Them

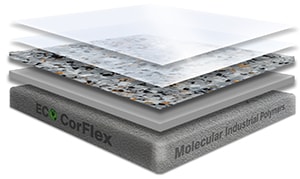

Our concrete coatings use an epoxy as the primer coat (we’ll never apply a polyurea or polyaspartic direct-to-concrete). We then apply our thermoplastic or mica-mineral full-flake blends into the “wet” primer coat; the chips get fully embedded in the thick primer. We then top the flake layer with dual coatings of our 100%-solids polyaspartic (not just one) to ensure maximum protection. But because we use an epoxy as the primer coat, our installations take 2 days…not 1…which is a great thing for our customers! It ensures the longevity of our coatings…and our warranty reflects our confidence.

Ultimately, our full-flake concrete coating systems far surpass “1 day” systems in quality:

- We use industrial-grade, 100%-solids liquid coatings

- We prime our floors with a moisture-mitigating epoxy (never a polyurea or polyaspartic direct-to-concrete)

- We offer our customers dozens of mica-infused flake blend options (not just thermoplastic)

- We top our full-flake coating systems with two 100%-solids polyaspartic coats (not just 1)

- Our finished full-flake systems are incredibly durable and over 35 mils thick

- We fully warrant our flooring against moisture-related issues and hot-tire transfer (no fine print exclusions)

Call us. Garage Floor Coating of New Jersey at (856) 933-9981. We’re your local concrete coating experts providing the most beautiful and durable flooring with a real warranty.

We also distinguish ourselves by using unique mica stone blends in several of our full-chip series of concrete coverings – going beyond usual thermoplastic flakes producing floors with increased thickness (leading up to 35 mils), strength and visual appeal For high quality, long-lasting commercial-grade garage floor coating solutions contact us as soon as possible via this link for your free estimate. We look forward to hearing from you!